Robot for cleaning and polishing

fused silica rollers for glass tempering furnaces

Robot for cleaning and polishing

fused silica rollers for glass tempering furnaces

MAIN WORKING FEATURES

The Robot Model “RoboClean” developed by Eurotech Way, is a Robot easy to use and completely

safe for cleaning and polishing. It removes dust and fused silica from rollers inside any type of

tempering furnaces made by different manufacturers.

The RoboClean is set up inside the furnace, at the starting point of the area that has to be treated,

it works simultaneously on two rollers ;

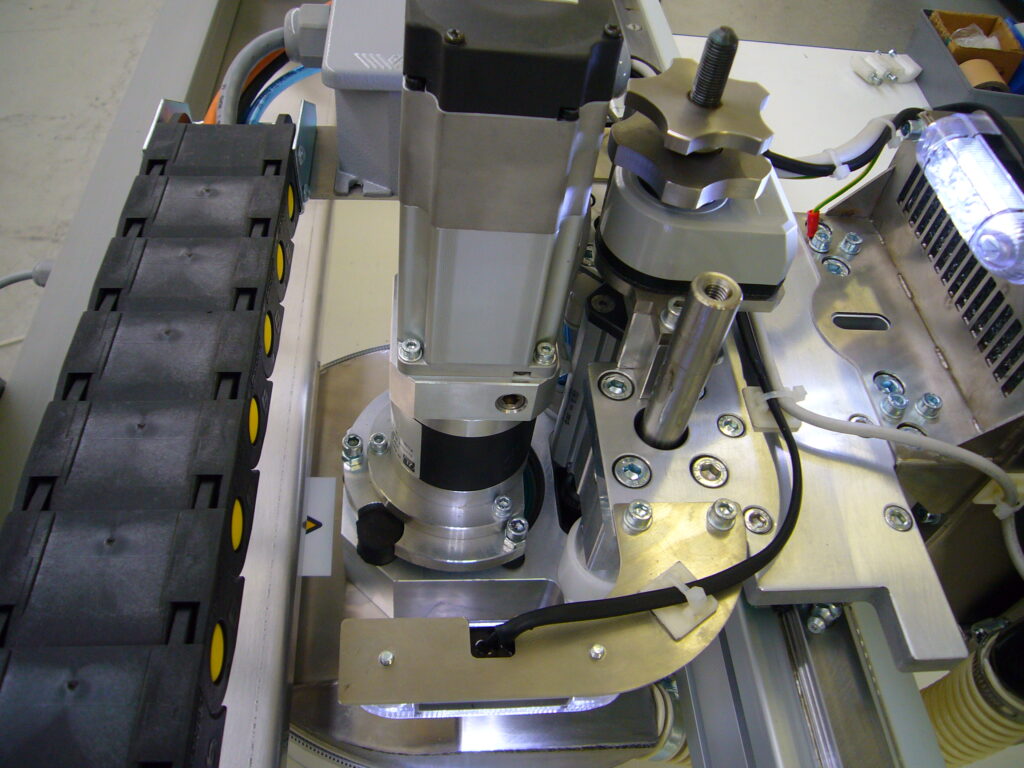

The “RoboClean” cleaning head is equipped with an automatic levelling and compensating

system, to guarantee an adjustable and constant pressure on the entire surface of the rollers.

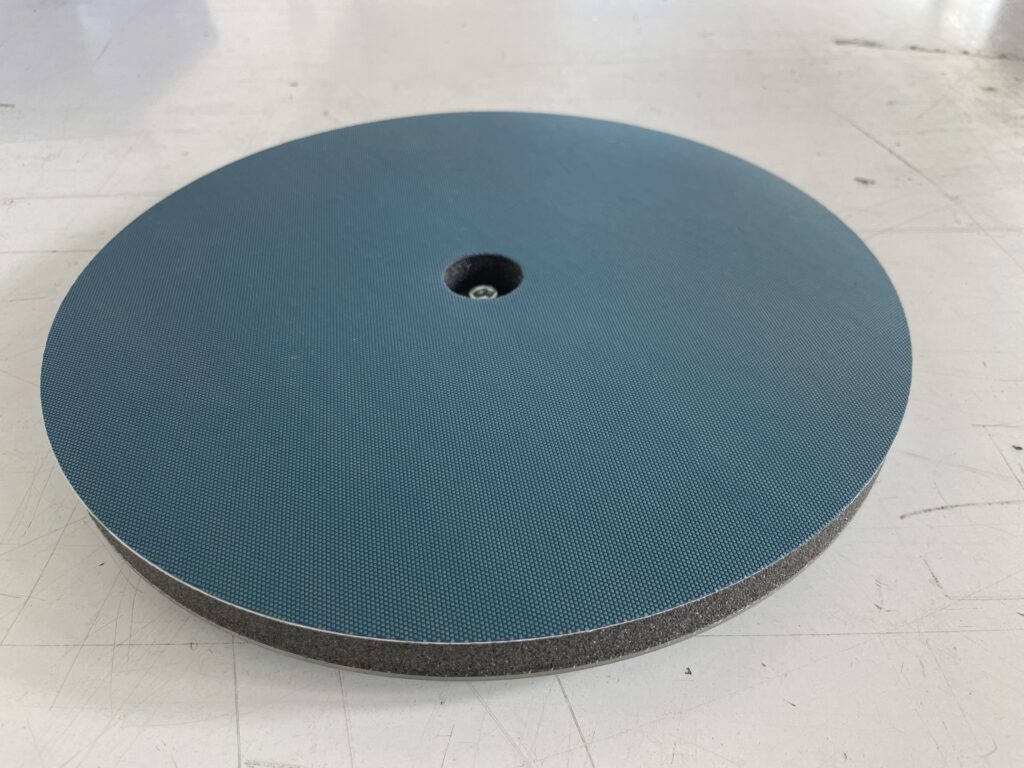

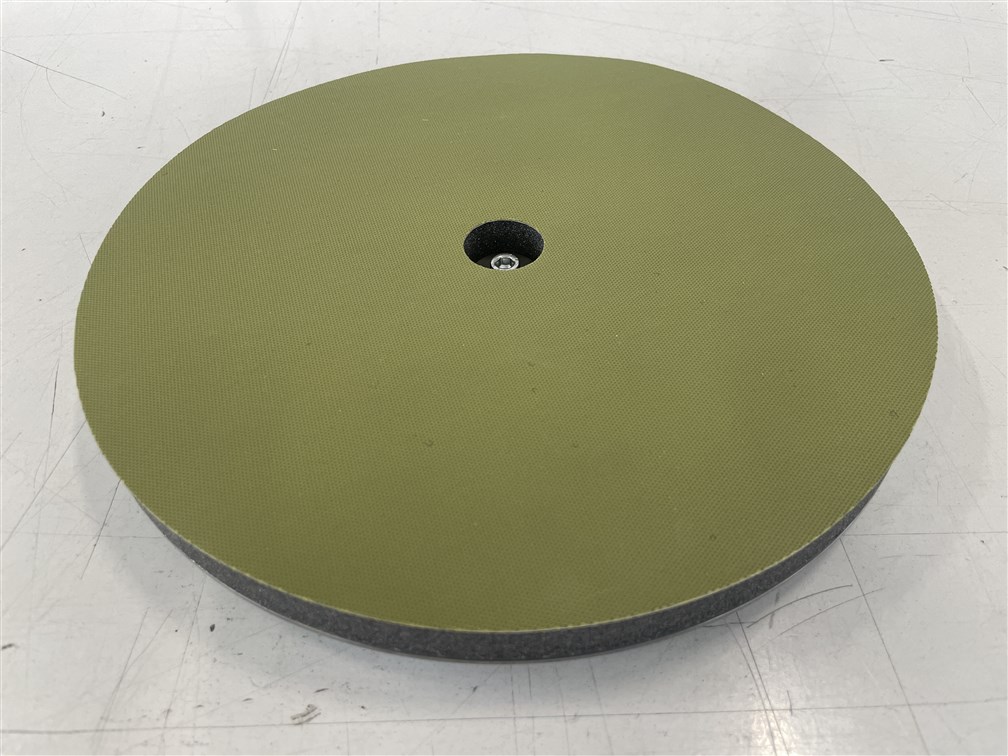

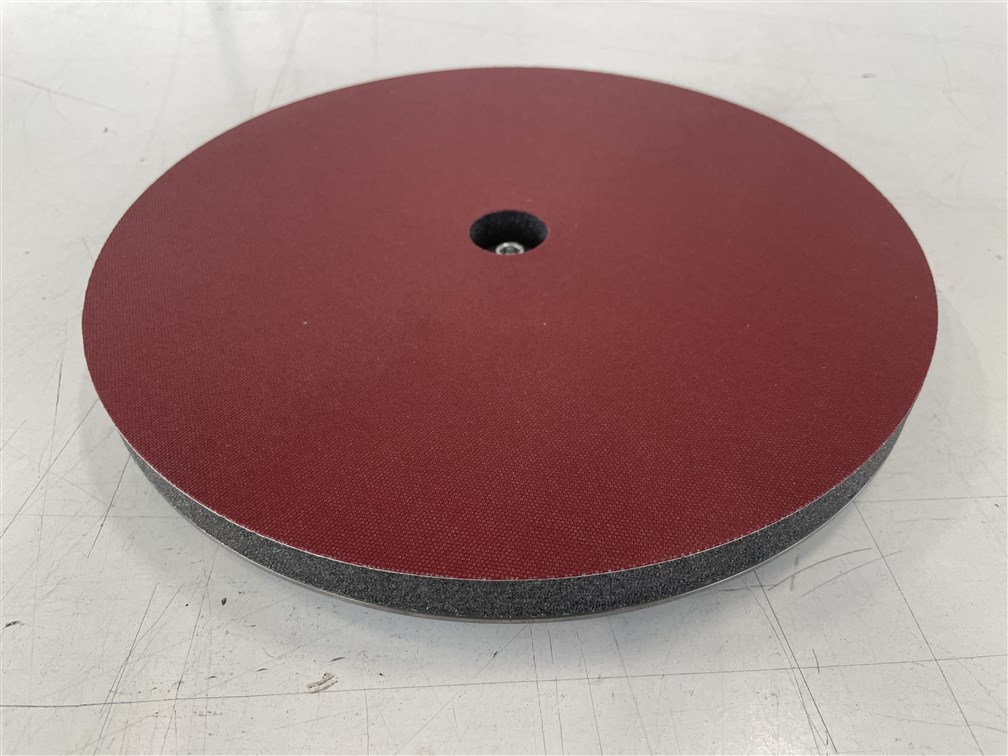

There are three different kind of tools; each tool has been projected to protect (and not damage)

the integrity of the rollers surface. The other accessories are made with soft materials in order to avoid any damage to the rollers, through the specific dumping system of the working head, thanks

to which the RoboClean is able to perform a delicate cleaning action.

A special disk, assembled with a series of rotating high resistance steel blades, will “cut and

remove” in an extreme, accurate and safe way, all residues of glass partickels or paint, (even

microscopic dimensions), from the rollers surface. These blades are totally independent and self –

leveling performing a non-abrasive action on the rollers. Their speed is variable, controlled and set

with brushless motor technology.

During the last phase of the cleaning process a specific disk made with a special fiber cloth,

removes any residual powder on the rollers surface, allowing the immediate restart in production

of the furnace.

The process ensures that the surface of the rolls, once cleaned, will be equal and sometimes

better than when the furnace has been bought!

The “RoboClean” Robot is equipped with a vacuum and filtration system (integrated with filter

clogging alarm which indicates the need to clean the filter), which allows the suction of

residual/removed powder.

“RoboClean” is equipped with a PLC installed in the Cabinet, that allows to manage and control all

RoboClean functions during working process. All parameters and working data can be set up using

A touch-screen operator interface.

The “RoboClean” can be used on different furnaces, since you can store all working parameters for

each different furnace.

The Customized Software of the “RoboClean” PLC shows on the screen all alarm description

associated with images, for an immediate identification of the problem.

Also in case of alarm activation the process will be immediately interrupted and the working head

will quickly lift up to avoid damages on rollers.

Moreover, thanks to the perfectly cleaned rollers your furnace will produce great quality glass

immediately from the re-start.

The complete process of dry cleaning is performed automatically ,therefore there is no need to

wash the rollers.

Dust and dirt (even if microscopic) are totally removed from the rollers surface because the

software controls, regulates and synchronize all movements of the cleaning head according to the

rollers rotation speed. For this reason, the entire surface of each treated roller, is perfectly

cleaned and polished